Dry, self-cleaning filters for steady airflow

Introduction

In a high-performance road sweeper, the airflow doesn’t just carry debris; it carries fine dust and moisture that can overwhelm filters if not managed. Pre-separation systems remove heavy grit, but fine particulates and humidity remain in the stream, and without active protection, they embed deep in the filter media. In tropical or monsoon conditions, moisture turns dust into sticky paste, causing filter caking, suction loss, and rising engine load long before the operator notices.

Most sweepers leave this burden to the final filter stage. Basic bag or panel filters face the entire problem without upstream support, humidity control, or self-cleaning. As a result, they clog early, require frequent manual blow-outs, and force operators into a reactive cycle of maintenance instead of steady performance.

Pulse Clean was built to break this cycle by keeping filters dry, clear, and continuously clean for consistent airflow all shift long.

Flawed filtration: what sweepers do wrong or don't do at all

In most machines, fine dust is left to the final filter stage. after basic pre-separation, dust-laden air is sent directly to a cartridge or cloth filter. the filters have to stop extremely small, and often sticky particles without any support. without upstream polishing stages (mentioned in cycloshieldTMM), humidity control, or proper filter cleaning, filters in standard sweepers often become overloaded early in the shift.

Filter loading and airflow issues in most machines

1. Filter type and its limitations

Most sweepers use flat-panel filters, non-pleated socks, or basic

bag filters made from cellulose or synthetic cloth. These formats are widely used because they’re cost-effective, simple

to install, and easy to replace. For manufacturers aiming to hit a functional price point, these filters offer just enough performance to capture visible dust under dry, controlled conditions.

Challenges:

However, these filters have very limited surface area, which means they clog quickly, especially when exposed to fine dust. The smaller media footprint offers less space for dust to settle, so even a moderate load clogs the filter fast. These filters also tend to hold dust rather than shed it, especially once moisture is present. As a result, airflow drops early in the shift, performance fades, and filters need frequent servicing or replacement, raising downtime and operating costs.

2. Cartridge placement and thermal Environment

Challenges:

But this distance from heat creates a major issue in wet or humid conditions. Cold compartments act like condensation traps. When warm, humid air hits these surfaces, moisture forms instantly, turning fine dust into sticky paste. Even high-grade media struggles when it’s wet. This encourages filter caking, drastically shortening usable filter life and accelerating suction loss.

3. Manual maintenance and shift disruption

Challenges:

This maintenance is time-consuming, labor-intensive, and easily skipped under field pressure. When it is skipped, filters clog mid-shift, suction weakens, fuel use climbs, and cleaning quality suffers. Operators often continue working with underperforming systems, unaware that the machine is far below spec. The result is a cycle of poor performance, rising maintenance effort, and escalating total cost of ownership.

How Pulse Clean keeps filters clear and suction strong

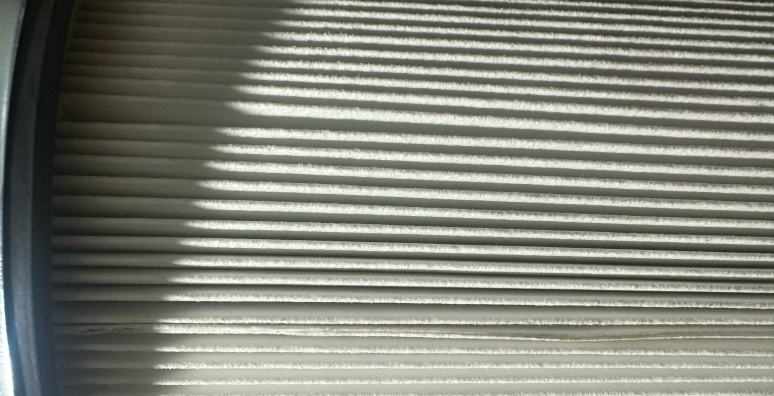

1. Pleated cartridge advantage

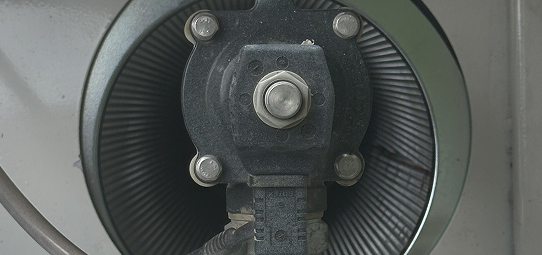

Stratus road sweeper uses rear-mounted pleated cartridge filters, not flat panels or bags. The rear-mounted pleated cartridge filters receive air that has already passed through upstream separation stages like an inertial separator and cyclone (Read more: CycloShield). Pleating greatly increases the filter’s surface area, allowing it to capture fine particles without clogging early in the shift.

Benefits:

More surface area means dust is distributed over a wider space, preventing overload. Filters last longer, airflow stays steady, and performance is more consistent, especially in dust-heavy conditions.

2. Humidity conditioning

Stratus sweepers mount these pleated cartridges beside the engine cowling, where radiant heat raises the bay’s ambient temperature. Incoming air that may carry up to 90% RH (relative humidity), especially in the rainy seasons or tropical areas, is conditioned down to 45–55% RH before touching the filter.

Benefits:

By lowering the relative humidity before filtration, Stratus road sweeper prevents condensation from forming on the filter, keeping the media warm, dry, and resistant to caking. This ensures consistent performance even in muggy monsoon conditions ot tropical climates.

3. Automated reverse Pulse Cleaning

Instead of relying on end-of-shift manual cleaning only, Pulse Clean fires a reverse pulse every 60 seconds from a 6-bar air reservoir. Dust is dislodged before it embeds into the media, preventing premature clogging during operation.

Benefits:

This keeps the filter clean continuously during operation, eliminating the need for mid-shift cleaning or intervention. Maintenance effort is reduced in frequency and intensity, significantly compared to traditional systems, uptime increases, and airflow stays within ±5% of its starting volume all shift long.