Multi-layer defense for cleaner air and longer life

Introduction

In a regenerative road sweeper, airflow isn’t just about suction—it’s the backbone of performance. That airflow doesn’t just pick up debris; it also carries grit, silt, moisture, and fine dust through the entire system. Effective sweepers don’t rely on just one filter to handle it all. Instead, they must separate different contaminants at different stages—from large debris at the curbside to PM10 particles before exhaust. Just as critical is managing how air flows between those stages: keeping the pressure balanced, the path smooth, and the system breathing cleanly from start to finish.

Most machines simplify this path. They use one or two separation steps and leave the rest to basic filters. That might work briefly on dry roads, but in real-world conditions, fine particles slip through early barriers, moisture clings to dust, and suction pressure fluctuates. With poor routing and unbalanced airflow, debris overloads the wrong components, filters clog too soon, and performance fades long before the job is done. A few missed design steps at the start become serious reliability problems in the field.

To maintain stable suction, clean airflow, and long filter life, a sweeper needs more than just a filter—it needs a strategy. That means combining multiple separation methods, each staged for a specific contaminant and designed to relieve the next one in line. Grit should drop out before it reaches the blower. Moisture should be stripped out before it hits the filters. And fine dust should be captured before it escapes. When air is cleaned in layers, pressure stays stable, parts stay protected, and sweeping performance stays consistent

Filtration challenges in standard sweeper designs

1. Separation

Conventional street sweepers typically rely on a two-stage or, at best, three-stage separation system. This usually includes

Gravity separation (where larger debris drops out due to reduced velocity),

Basic screening or grilles to catch oversized items,

A single-stage centrifugal separator or cyclone that removes medium to coarse particles using swirling airflow.

These systems are simple, cost-effective, and require minimal energy input or space, making them attractive for budget-conscious builds.

Challenges:

This simplified setup often misses ultrafine particles, moisture-laden silt, or sticky contaminants that don’t separate easily with just cyclonic force or gravity. The result is a high burden on the filter media. In humid environments, sticky fine matter bypasses separation entirely and lodges directly in the filters. This causes premature clogging, poor suction, and erratic airflow performance mid-shift.

2. Protection (of Internal Components and Exhaust Quality)

Challenges:

3. Airflow and Thermal Conditioning

In standard sweepers, airflow is usually direct, unbalanced, and unregulated. Air is pulled straight from the pickup head into the separator and filter box with little control over velocity, pressure, or turbulence. Thermal management is typically nonexistent, filters are placed far from heat sources to avoid warping or fire risk, and no active moisture conditioning is applied.

Challenges:

How CycloShield filters better and lasts longer

1. Multi-Stage Separation

In the Stratus road sweeper, CycloShieldTM delivers true multi-stage separation, tackling debris, silt, and fine dust through a progressively layered approach. Each stage in the airflow journey uses a different separation method gravity, misting, impact, centrifugal force, and filtration. This approach makes sure that there is no single point of failure, and every type of particle has multiple chances to be intercepted before reaching the final filter.

The multiple steps in the separation solution are:

Gravity-assisted drop and misting slow the airflow and knock out coarse grit early on.

Roof-mounted debris grill catches oversized trash, like plastic, cloth, or bottles, that bypasses the pickup head.

Primary cyclone removes silt and mid-size particles using centrifugal force.

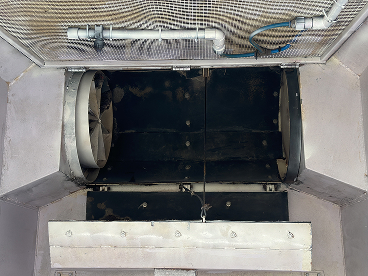

Linear inertial separator shears out ultrafines and moisture by forcing sharp airflow direction changes.

Secondary micro-cyclone polishes the airstream, catching finer residual dust.

Engine-warmed cartridge filters capture PM10 particles while avoiding condensation buildup.

Benifits

Beyond filter protection, multi-stage separation also benefits internal component life. It keeps impellers, ducts, and filter housings cleaner by stopping abrasive grit and wet silt farther upstream. And because the airstream is cleaner, the exhaust to the atmosphere at the end is clean and safe, making CycloShieldTM not just a filter strategy, but a system-wide defense against performance degradation, premature wear, and environmental leakage.

2. Protection For Both Machine and Environment

Benifits

3. Airflow and Thermal Conditioning

Benifits

By conditioning airflow early, CycloShield prevents the chaotic, high-velocity surges that can overload filters in uneven patterns. This means no hotspots, no sudden pressure spikes, and no shock loads on the filters. It also maintains more consistent suction pressure at the pickup head, improving debris capture. The clean atmospheric exhaust and stable airflow preserve system efficiency, reduce fuel consumption, and extend the service life of downstream filtration components. Pulse Clean then builds on this foundation with thermal protection and automatic filter cleaning, making the full Stratus system more resilient, balanced, and efficient across all environments.

CycloShield isn’t just a filtration system—it’s a design philosophy built around layered defense, stable airflow, and component longevity. By managing contaminants early, conditioning the airstream intelligently, and relieving stress on every downstream part, it transforms how a sweeper performs over time. The result isn’t just cleaner streets—it’s a machine that runs smoother, lasts longer, and delivers consistent results in every environment, every shift.