Precision airflow powers high-efficiency sweeping

Introduction

In a road sweeper, everything begins on the ground. No matter how advanced the filtration or airflow system is further upstream, none of it matters if debris, dust, and grit aren’t picked up effectively at street level. This pickup process involves more than just suction; it requires a combination of force to dislodge stubborn material, a clear pathway to collect it, and a sealed environment to keep dust from escaping. A truly effective pickup head must achieve all three, seamlessly and continuously.

However, most sweeping systems fall short at this first contact point. Mechanical broom-based sweepers rely on friction to scrape the surface, which wears down quickly and often misses embedded particulates. Vacuum-only systems lack the velocity to dislodge compacted dust or heavier debris. Airflow is typically uneven across the pickup width, and sealing is dependent on rubber skirts that degrade over time. As a result, coverage is inconsistent, dust escapes through micro-leaks, and operators are forced to compensate with extra passes or live with incomplete cleanup.

A high-performance pickup system needs to actively break the bond between dust and pavement, recover everything in a single pass, and prevent what’s been captured from leaking back into the environment. That requires more than suction; it calls for directional air force, synchronized airflow, and passive containment, all working together. This is the design philosophy behind the Air Blaster regenerative head.

Debris pickup limitations in conventional sweepers

1. Dislodging debris

Most traditional sweepers rely on mechanical brooms or basic suction to remove debris. Mechanical sweepers use rotating brushes to scrape surface material, while pure vacuum machines depend on suction alone. Some regenerative models introduce low-velocity airflow to assist in nudging debris toward collection paths, but without focused impact.

Challenges:

These methods fail to dislodge particles embedded in the road texture. Mechanical brushes wear quickly, struggle with uneven surfaces, and can’t access fine particulates trapped in micro-crevices. Suction-only models often leave behind heavier grit or stuck-on silt. The result is a superficially clean road still holding fine dust, leading to premature filter clogging, recontamination, or resuspension.

2. Debris recovery, coverage & performance integration

Challenges:

3. Containment and sealing

Challenges:

How air blaster combine dislodging and clean recovering

1. Dislodging debris with precision force

Stratus road sweepers use the Air Blaster pickup head, which channels airflow from the impeller into a razor- thin “air-knife” slot positioned just 25 mm above the road. This air-knife creates a high-velocity sheet of air, or an air curtain, racing at over 300 km/h that blasts across the pavement. Unlike traditional airflow systems that rely on general suction, this concentrated blast drives deep into the pores and surface texture of the road, dislodging compacted dust, embedded grit, and stubborn fine debris that lighter airflow would miss.

Benifits

This precision dislodging allows Stratus to reach deeper into the road surface than conventional sweepers, removing material that mechanical brooms or pure-vacuum heads typically leave behind. The result is a cleaner sweep with fewer passes.

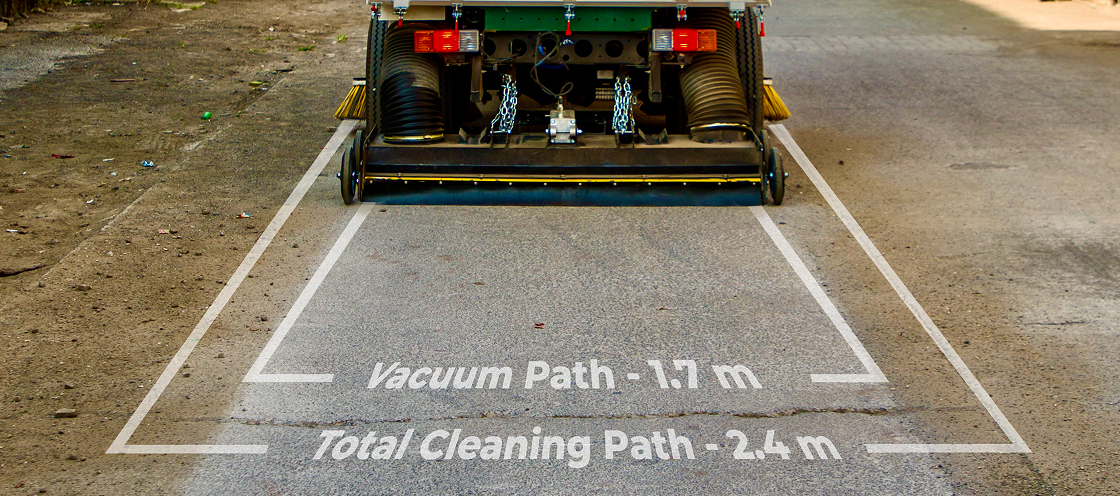

2. Wide-area recovery and consistent coverage

Benifits

3. Dust containment through pickup head sealing

Benifits

Most sweepers compromise between reach, recovery, and containment, solving one problem at the expense of another. The Air Blaster regenerative pickup head breaks that pattern. By combining dislodging power, synchronized airflow, and fully integrated sealing, it transforms the sweeper’s front line into a precise, high-efficiency cleaning system. Whether it’s fine dust embedded in rough asphalt or bulky litter skimming the curb, everything is targeted, captured, and contained—without recirculation, rework, or dust trails. It’s not just how Stratus sweeps—it’s how the job gets done right the first time.